Frequency Electronics Inc. is a non-traditional, vertically integrated, small business.

FEI provides a unique product suite including master clocks, GPS timing systems, and multi-frequency generation systems to a diverse base of government and commercial customers.

With a proven track record with a 50-year legacy in space, FEI’s products are used in mission critical systems where accuracy and reliability of time and frequency products are vital to the entire platform.

Manufacturing Capabilities

- FEI manufactures all quartz crystal resonators for space applications at this facility

- Quartz material procured from select qualified suppliers (premium Q, swept quartz)

- All processing performed at FEI (cutting, x-ray crystallography, lapping, polishing, contouring, plating, tuning, and sealing)

- FEI has invested over $1,000,000 in capital equipment in the last 3 years

- Improved x-ray capabilities

- Improved cutting equipment

- FEI manufactures all rubidium lamps and cells at this facility

- Glassblowers trained in specific materials and tasks associated with Rb cells

- Fully equipped facility (glass lathes, glass annealing furnaces, vacuum processing stations

- Rb cell manufacturing is continuous, independent of GPS and other space programs; commercial production utilizes the same trained staff and processes

- Test ATE

- 1 DC/DC Converter test set on-site

- 3 Module/subassembly semi – automatic test sets on-site

- 5 System level test sets

- Environmental Tests Performed In-House

- Thermal Cycling Performed

- Thermal Vacuum Performed

- 15 TVac Chambers currently on-site

- Vibration Performed (Qty 5 Vibration Platforms)

Engineering Capabilities

- In-house Resources

- Technical staff in place to execute the program with over 1000+ years of space/high-reliability experience

- All Critical Analyses Performed In-House

- Worst Case

- Component Stress

- Thermal

- Radiation

- Structural

- Reliability/FMECA

- EMC

- Phase Noise and Spurious Signals

- Fatigue

Manufacturing Equipment

- MyData MY100 LXe-10 Automatic Pick & Place Machine

- Capacity to hold 112 8mm feeders

- 6,500 CPH ( 22 LCV Module/hour vs 3 Modules/day using the semi- automatic machine)

- Electrical verification on resistors, capacitors, diodes before placing parts on PCBs

- Ability to use barcode for faster feeder set-up time

- Essemtec EXPERT Semi-Automatic Pick & Place Machine

- Manual and semiautomatic models

- Smooth gliding arm system

- Air suspended pick-and-place head

- Integrated placement illumination

- x/y/t fine-adjustment

- Automatic component lowering to PCB

- Microprocessor control with LCD

- Glue and solder paste dispensing system

- Essemtec FINO Semi-automatic Stencil Printer

- FEI has upgraded to a Semi Automatic machine to improve solder consistency

- Software Control functionality:

- The speed at which squeegees movement across the stencil apertures

- The force applied onto the squeegees blades during the printing of the solder paste

- The releasing of stencil from the PCB after paste being applied

- Aqueous Technologies Trident-XLD Automatic De-Fluxing and Cleanliness Testing System

- Flagship model of the Trident Series

- Automatic De-Fluxing

- Improves solder ball and flux removal.

- Real Time cleanliness testing

- Controlled by a Windows-based PC computer

- Automatically captures all relevant process data including cleanliness testing results (SPC)

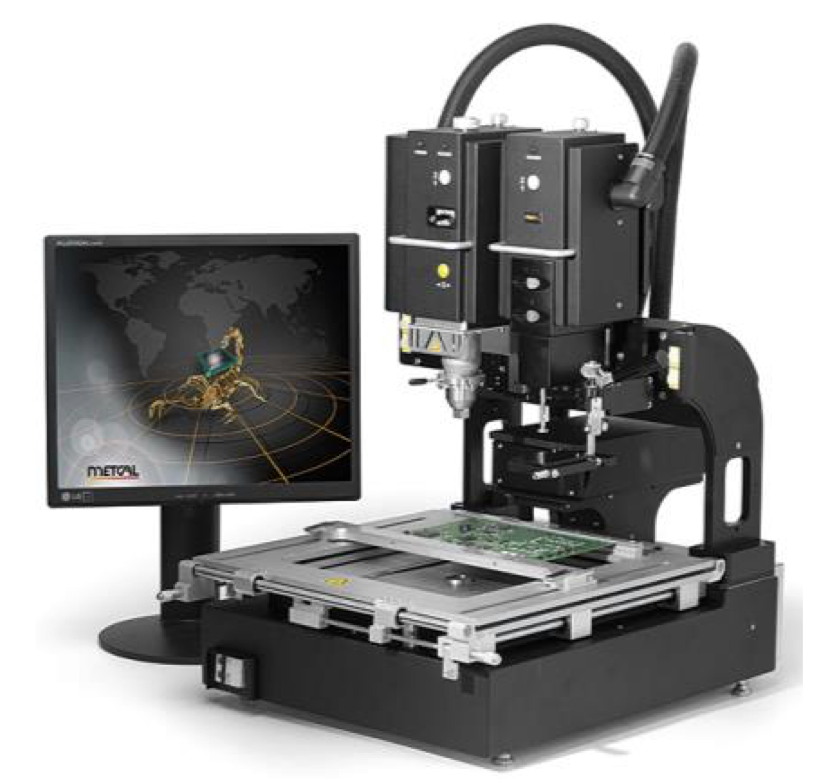

- Metcal Scorpion APR-1200-SRS Advanced Package Rework

- Station meets the challenges of array package rework and the accurate placement required for the smallest BGAs, QFNs and Micro SMDs

- It can create specifically tailored reflow profiles through unique convection heating technology with nozzle and dual-zone pre-heater in one user-friendly, single platform rework system

- Precision Valve & Automation PVA350 Automatic Dispensing System

- Little or no masking of PCB is required

- Flexible dispense and spray head

- Very easy to program

- Process is very accurate and repeatable

- Automatic Optical Inspection – ALeader ALD525 i3D

- i3D Height Analyzing, coplanarity check, and Shape Analysis. Able to analyze wetting angles, height, and overall topography of PCB

- Debug-Free Technology (Including flexible packages)

- Escape-Free Technology

- False Calls Control Technology

- Small Chip: Coplanarity, offset, cold soldering, no solder, missing, tombstone and more

- Production Process Control SW: prevent defects in real time, improve and control production

- Real Time x-ray – Investigating systems similar to Unicomp Technology Ax-8600HR

- 100 KV 5um X-ray Tube (130 KV option)”Arc” Motion

- High-resolution Detector with 60 o tilt

- 2 mega pixel CCD camera with navigation

- Multi-function work station with 360o rotation

- Wide detection area up to 550mm*500mm with 420x Geometry Magnification

- Automatic rising-lowering and scale mark

- Intuitive interface, Ease of Operation

Facility

FEI’s Hi-Rel assembly and test areas include:

- Six class 10,000 clean rooms – 7,500 Sq. Ft

- Critical processes under class 100 laminar flow

- High reliability assembly and test areas – approx. 13,000 Sq. Ft (10,000 + 3,000 lower level)

- Environmentally controlled

- Particle arrestment and count, temperature, relative humidity, ESD

- Monitored as class 100,000 (typically 50 – 60K)

- Environmentally controlled

Technologies

- Crystal fabrication and test

- Rubidium lamp and cell fabrication and test

- Thick and Thin Film Hybrid assembly and test

- Multi-technology modules

- Surface Mount Technology (SMT)

- Automatic and semi-automatic assembly

- Automatic Optical Inspection

- Real Time X-Ray

Parts, Materials and Processes (PMP)

- FEI maintains an extensive Inventory of Hi-Reliability parts

- Over $12.5 million

- Ensures meeting schedule requirements on current programs as well as newly bid Programs

- The Materials and Processes FEI incorporates in the manufacture of space hardware has been approved by every major Aerospace Customer

Testing Approach for Production

- Testing will be accomplish using manual and automated system as required.

- All technicians are trained to test space programs

Operator Certification & Ongoing Training

- Assemblers are certified to NASA STD 8739 and WSM-100

- Trainer Certified to NASA STD -1, -2, -3 (Conformal Coating & Staking, Surface Mt Soldering, Hand Soldering respectively)

- Assemblers and Technicians are ESD trained in accordance with 33770-PRO

- Employees are trained to WSM-100 FEI Workmanship Specification

- Operators are certified to all processes they are assigned to.

- In-house NASA-STD-8739.1, .2, .3 Level B Instructor

- Manufacturing personnel have received the proper training to build the assemblies.

- Certified Operators and Inspectors per :

- NASA-STD-8739

- NHB 5300.4 (3J)

- WSM 100

- Training records are available (on-site review only)

Test Equipment

- System ATE

- EPC ATE Test Rack

- Input bus source from 20V to 120V pulse command (positive & negative)

- EPC with 1 to 5 outputs, output power from 5W TO 200W, output voltages from 1.5V TO 50V

- EPC test capacity (Isolation, Continuity, Output Ripple, Load Switching, Low Bus Latchoff, Command Turn-on/Overshoot, Inrush Current, Switching Spikes, Minimum Load Margin, High Speed Bus Fluctuation, Voltage Regulation, Efficiency, Status Telemetry, Switching Frequency, Undervoltage Lockout, Frequency Domain Ripple, Short Circuit Test)

Hybrid Equipment

- West Bond

- Semi-automatic wire bonder and thermosonic ribbon bonder

- Eutectic/Epoxy Pick & Place die bonder

- SST International Eutectic Reflow Station

- Void-Free Eutectic Die Attach

- Fiber Optic Package Assembly

- Ceramic Package Sealing

- Flux-Free Solder Process Development

- Assembly of Microelectronic Packages

- Hybrid Microelectronic Circuit Assembly

Quality Equipment

- Nitron and Fisherscope x-ray incoming inspection equipment to analyze parts for prohibited content such as pure tin, cadmium, and zinc

- Thermo Scientific Niton Metal & Alloy Analyzer

- 50 kV x-ray tube provides approximately 2x the x-ray flux of a 40 kV x-ray tube

- Fast, nondestructive verification of high-temp, nickel, titanium, aluminum alloys & superalloys

- Confirmation of presence / absence of high-purity Sn – prevent Sn whiskers before they start

- Identify Se, Cd, and Zn coatings for space applications – don’t let them sublimate in a vacuum

- Shorter measurement times

- Lab-quality accuracy and precision

- Fisherscope x-ray XDAL

- Spectrometer with silicon PIN detectors provide reliable analysis results and coating thickness readings even with a small concentration and very thin coatings

- Designed for electronics and semiconductor industries

- Analysis of very thin coatings, e.g. gold and palladium coatings of = 0.1 μm

- Fast and highly precise XY(Z) measuring stage

- Excellent long-term stability, which is reflected in a reduced calibration effort